News

Stack Metallurgical News

Keeping Up-to-Date

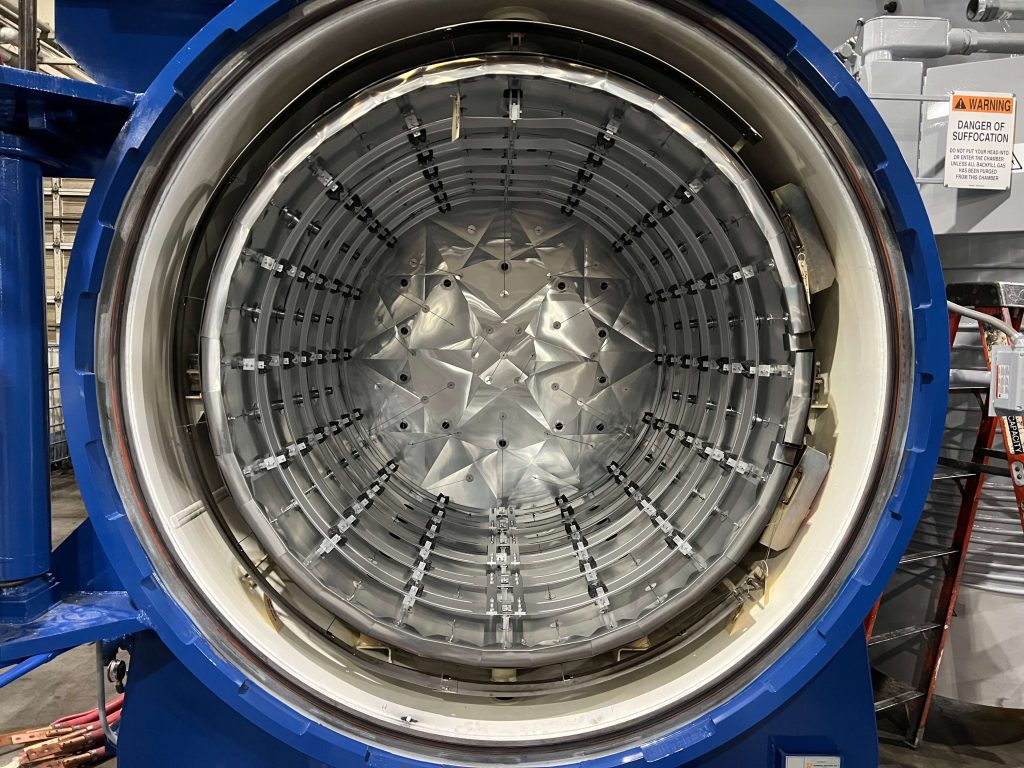

June 2023 - STACK PORTLAND ANNOUNCES INSTALLATION OF A NEW 6 BAR IPSEN TURBOTREATER

Stack is continuing to show our commitment to excellence by investing in a brand new 6 Bar quenching, Turbotreater horizontal vacuum furnace from Ipsen. This is more than a purchase; it’s a substantial investment in our facilities and, more importantly, in our valued customers. This advanced technology will allow us to increase our heat treating offerings, and ensure superior results for our customers. The enhanced precision and control offered by this equipment will open up new possibilities for our customers across various industries.

June 13th, 2022 - 2022: Meet The Women of PNAA - Including our Own Kimberly Chaussee

This video by one of Stack Metallurgical Group’s partners, Pacific Northwest Aerospace Alliance, highlights the important role women have played in the aerospace industry. One of our own employees, Kimberly Chaussee, is featured in this video!

September 30th, 2021 - Stack Service Spotlight: Noah Bernert & Conner Fischer

Congratulations to our Stack Service Spotlight recipients for the month of September, the Stack Portland Pyrometry team of Noah Bernert and Conner Fischer. Pyrometry is a critical and integral part of Stack’s operations. Pyrometry is the process of measuring the temperature and uniformity of a furnace during the heat treat cycle, which ensures that it has been properly heat treated.

In order to maintain this level of quality, it is vital that we have a team of people who are dedicated to the highest standards. Since taking over this department, these gentlemen have had zero findings on their Nadcap audits for three consecutive years now! In addition to running a tight department, Noah and Connor have been able to secure over 160 hours of training in the past year. Not only are they great teammates, they are both true leaders in our facility. We are lucky to have both Noah and Conner on the team at Stack!

July 29th, 2021 - Stack Service Spotlight: Bruce Hausinger

The team at Stack would like to recognize Bruce Hausinger as the recipient of Stack Service Spotlight for the month of July. Bruce joined Stack in October 2020, filling a critical position in our Lab department. He has worked hard to understand our business and has quickly taken on a leadership role and has become an integral part of not only our Lab, but Stack’s ongoing success. Bruce has quickly become a “go to” person that both the team at Stack and our customers can depend on. Bruce’s positive attitude and willingness to take on new challenges have made him an excellent addition to the team. We are lucky to have Bruce as a part of Stack!

The team at Stack would like to recognize Bruce Hausinger as the recipient of Stack Service Spotlight for the month of July. Bruce joined Stack in October 2020, filling a critical position in our Lab department. He has worked hard to understand our business and has quickly taken on a leadership role and has become an integral part of not only our Lab, but Stack’s ongoing success. Bruce has quickly become a “go to” person that both the team at Stack and our customers can depend on. Bruce’s positive attitude and willingness to take on new challenges have made him an excellent addition to the team. We are lucky to have Bruce as a part of Stack!

July 12th, 2021 - Stack Expands Hot Isostatic Press Services with Addition of Quintus QIH-122

Following the successful launch of Stack HIP in 2020, the team at Stack is pleased to announce the commissioning of a second Hot Isostatic Press (HIP) from Quintus Technologies. The addition of the QIH-122 allows Stack to offer the latest high-pressure and rapid cooling HIP technologies, and to better service our partners in the additive manufacturing, medical implant, aerospace, defense, power generation, and other manufacturing industries and their supply chains. Download the Press Release to find out more!

May 17th, 2020 - Stack Service Spotlight: Hector Castillo

Hector is one of our most versatile employees. He brings a smile and positive attitude every day and with every task he performs. Hector can be found anywhere on the shop floor where work needs to be done. From endothermic heat treating, to aluminum heat treating, vacuum heat treating, to straightening – Hector does it all, and he does it extremely well! Thank you, Hector! We are beyond privileged to have you on our team!

January 22nd, 2020 - Stack Metallurgical Group Sites Achieve Nadcap Merit Status

Inland Northwest Metallurgical Services in Spokane, WA, has been awarded Nadcap 24-month merit status.

Aerospace Aluminum Processing in Salt Lake City, UT has been awarded Nadcap 18-month merit status.

Stack Metallurgical Group, one of the largest heat-treating providers in the Western United States, is pleased to announce that two of their sites have once again earned NADCAP accreditation. These locations demonstrate an ongoing commitment to quality by meeting industry specifications and satisfying customer requirements.

Nadcap is an industry-managed approach to conformity assessment that brings together technical experts from both Industry and Government to establish requirements for accreditation, accredit Suppliers and define operational program requirements. This results in a standardized approach to quality assurance and a reduction in redundant auditing throughout the aerospace industry

Nancy Brummel, Quality Director at Aerospace Aluminum Processing, stated: “It truly was team effort by everyone at ASAP. The only way to achieve high quality standards is to have every member focused on quality. This commitment to quality is displayed through our finished customer product and our high level of customer satisfaction.”

2020 was an extremely busy year for Stack Metallurgical Group. In addition to the recent audits in Spokane and Salt Lake City, Stack Portland completed a successful Nadcap audit this summer, and Stack HIP in Albany, Oregon received its initial Nadcap certification in April.

November 19th, 2020 - Stack Service Spotlight: Brice Winney

Stack would like to recognize General Manager Brice Winney for his leadership in launching our new HIP facility this year. With over 15 years of aerospace and high-tech manufacturing experience, Brice was instrumental in ensuring our facility integrated quality and efficiency measures for our Hot Isostatic Press services. Brice and his team tackled the challenge of establishing a new facility and delivering outstanding product and service to our trusted clients. If you want to congratulate Brice, you’ll have to wait until he returns from his well-earned vacation – elk hunting!

September 4th, 2020 - Stack Service Spotlight: Sheng Thao

On behalf of Stack Metallurgical Group’s management team, we would like to recognize Sheng Thao as Stack’s Service Spotlight recipient for the month of September. Sheng works as a Furnace Operator in the Vacuum department at our Portland, Oregon facility. She joined the Stack team in 2018, and over the last two years has quickly expanded her knowledge of heat treating and taken on greater responsibility within the shop.

Sheng is always willing to help customers and her fellow teammates wherever and whenever the need is required. Her constant willingness to help others, positive attitude, and exemplary performance make Sheng the ideal candidate for Stack’s Service Spotlight. Sheng’s favorite aspect of working at Stack is that everyone is dedicated, motivated, and inspired. Thank you for your hard work and effort Sheng, we are lucky to have you on the Portland team!

July 31st, 2020 - Stack Service Spotlight: Bob Lewis

We would like to recognize Bob Lewis for earning the Stack Service Spotlight award for the month of July. Bob is the Quality Manager of the Stack HIP facility, located in Albany, Oregon. As a degreed metallurgist, he is a technical leader within the Stack Metallurgical Group (SMG) in addition to adeptly managing all of the Quality functions at the Albany facility.

Bob works very hard to help make Stack HIP a leader in the world of aerospace metal post processing. He ensures that every quality-critical part that leaves the Stack HIP facility has been processed to the absolute highest standards for quality.

In his free time, Bob enjoys being outdoors, and he can be found cycling, running, or gardening. Bob’s favorite aspect of his job is the flexibility of being able to use his technical abilities with a strong quality emphasis to understand and methodically work to streamline and improve Stack’s processes. Bob, we thank you for all you have done for not only Stack HIP, but the company as a whole! Congrats Bob!

July 23rd, 2020 - Stack HIP Receives Safran Aircraft Engines Approval

Stack is proud to announce that our Stack HIP facility based in Albany, Oregon has been awarded approval from Safran Aircraft Engines. Stack HIP also holds NADCAP certification for Hot Isostatic Pressing. We look forward to continuing our history of providing the highest quality services and solutions to the aerospace and defense industries. This approval will assist Safran to continue to advance towards playing a real part in developing engine architectures. “We are proud to have worked diligently alongside one of the biggest engine manufacturers in the industry” said Brice Winney, General Manager of Stack HIP.

June 30th, 2020 - Stack Service Spotlight: Dawn Stubblefield

It is our pleasure to present Dawn Stubblefield with Stack Metallurgical Group Service Spotlight for the month of June. Dawn has been with us for over eight years, is a driving force at our Spokane facility.

Dawn has a tremendous eye for detail when it comes to customer service and is constantly going above and beyond with our customers in an effort to improve their experiences. We are always amazed at the new initiatives Dawn champions to ensure our customer expectations are consistently exceeded. Dawn’s favorite part of working for Stack is that she is able to meet new people and build great business relationships with our customers.

When Dawn is not at Stack, she loves spending time with her family hiking, camping, or hunting. She also likes to travel to new and scenic locations all over the country.

Dawn is the exact kind of professional that every organization needs, and we are lucky to have her!

June 12th, 2020 - SMG Launches Production Of New HIP Process Installed by Quintus

Stack is in the news! Read the Industrial Edition of Titanium Today to find out more about Stack state-of-the-art HIP manufacturing facility and the unique advantages of combining HIP and heat treatment for industries such as – additive manufacturing, aerospace, and medical implants.

June 3rd, 2020 - Stack IS PROUD TO NOW OFFER BLACK ANODIZING POST PROCESSING

Stack Metallurgical Group is proud to announce that we have expanded our high-quality metal finishing services to include Black Anodizing. Black Anodizing is a process by which the surface of an aluminum component is carefully oxidized to create a non-conductive layer with a cosmetically uniform black color.

This type of finish is very popular with a range of industries including aerospace, outdoor recreational equipment, and firearms, just to name a few. By offering this process along with our existing range of aluminum surface treatments, we now have even more solutions for nearly any product and application. As with all of our metal processing services, we pride ourselves on quick turnaround, superior quality, and outstanding customer service.

May 29th, 2020 - Stack Service Spotlight May Recipient: Kimberly Chaussee

When Kimberly joined Stack Metallurgical Group nearly 10 years ago, she fervently exhibited one of our most important company values of always putting the customer first. A well respected leader in her role as Production Control Supervisor. Kimberly oversees all pricing, invoicing, and customer service. She works to coordinate customer’s orders with the production staff. Earlier this year, Kimberly was promoted to Production Control Manager.

Kimberly is truly one of the most pivotal parts of our production process. She is constantly looking for ways to improve our internal processes to better optimize our service offerings for our customers.

In Kimberly’s free time she can be found in the community teaching women and children’s self-defense classes. Stack is not the only organization to who have recognized Kimberly’s constant willingness to help others and go above and beyond the call of duty. She has received the “Police Chief’s Award” from the City of Fairview for “showing genuine care and compassion for the safety of our citizens”.

April 17th, 2020 - Stack Service Spotlight February Recipient: Joe Lafayette

On behalf of the Stack Metallurgical Group management, we would like to extend our appreciation for the amazing work done by our own Joe Lafayette. Joe is an integral team member at our Spokane facility. With over 10 years of experience with vacuum heat treating, he serves as one of our heat-treating experts in the company. Joe routinely works on weekends and holidays enthusiastically to ensure orders are delivered to customers correctly and on time.

His diligence, expertise in AMS specs and heat treating, self-motivation as well as dedication to always go the extra mile in order to achieve the best possible results for our customers is what makes Joe stand out. In his free time Joe can be found spending time with his family, hiking, or mountain biking. He also fills leadership positions at his church. The team at Stack recognizes the amount of effort that you put into your job every day. Thank you for your hard work and effort, Joe. We are lucky to have you on our team!

April 8th, 2020 - Stack HIP Achieves Nadcap Accreditation for Hot Isostatic Pressing

Stack HIP, a division of Stack Metallurgical Group (SMG), has achieved Nadcap certification for its new facility in Albany, Oregon. Nadcap is a global cooperative accreditation program for aerospace engineering, defense and related industries. With this approval, Stack will be offering Hot Isostatic Pressing (HIP) services to North American manufacturers supporting the aerospace industry.

“Achieving Nadcap certification for Stack HIP is truly a team effort,” states Brice Winney, Stack HIP General Manager. “Having this certification allows us to provide HIP services for our primary aerospace customers. It also reflects on the high attention to detail within our team for safety, quality, and operational excellence.”

SMG now offers four Nadcap-accredited locations with a focus on aerospace, power generation, medical implant, and high-end knife and cutlery markets. The company’s modern and extensive equipment lineup offers a comprehensive portfolio of services for demanding clients throughout North America.

March 27th, 2020 - Critical COVID-19 Support

The full resources of the Stack Metallurgical Group are available to any manufacturers supporting our efforts against the COVID-19 pandemic. Capacity for the processing of any medical and/or ventilator components, 3D printed/additively manufactured parts, tools and dies, or anything else related is immediately available.

All capacity that we can offer is available free-of-charge to our manufacturing partners. Our team of metallurgists and engineers are also available to provide any knowledge-based support. Please contact the Stack team and let us know how we can help!

#metalpostprocessing #heattreating

-The Stack Metallurgical Group

March 23rd, 2020 - Together We Rise/COVID-19 Update

Stack Metallurgical Group operates four facilities that provide Heat Treating and Metal Processing services to a range of industries.

As Heat Treating falls within the Primary Metals Manufacturing, Critical Manufacturing Sector, all of our locations remain open to support the continuing needs of our customers.

The safety, health, and well-being of our employees remains our top priority, and we have therefore adopted a number of policies to protect our team.

We appreciate your patience and support as we strive to maintain our high standards for quality and customer service during this challenging period.

If there are any future developments which result in a temporary closing of a Stack facility, we will make every effort to directly contact impacted customers.

Thank you, and our very best wishes to everyone!

Doug Puerta

CEO, Stack Metallurgical Group

March 6th, 2020 - Stack's Hot Isostatic Pressing (HIP) Facility Completes Nadcap Audit

We are proud to announce we have completed our Nadcap audit for our hot isostatic pressing facility in Albany, Oregon. This diligent and meticulous process would not have been completed without the hardworking staff at our Albany site, and our partners, Quintus Technologies and Messer Group. We are expected to be officially Nadcap accredited in mid-late April. Keep checking back for more information. If you are interested in partnering with Stack for your HIP needs, please feel free to reach out to us here: https://www.stackmet.com/contact-us/

#hotisostaticpressing #metalpostprocessing #aerospacemanufacturing

February 27th, 2020 - Stack Service Spotlight February Recipient: Nancy Brummel

We would like to recognize our own Nancy Brummel for her outstanding work in her role as the Quality Director of Aerospace Aluminum Processing. Nancy has a rich history in the aerospace industry. She began her start at Hill Air Force Base as a Crew Chief on the F-16 Fighter, as well as working on the assembly and fabrication of the MD-11/MD80 at McDonnell Douglas. All these experiences and more made Nancy the perfect candidate for the role of the Quality Director at our Salt Lake City facility.

Nancy has been in the role for over 20 years and ensures that all aerospace components leaving the SLC facility are of the utmost quality. She does this while maintaining the highest degree of customer service. She helps our customers with throughput, quality, and cost reduction. Thank you, Nancy, for your exemplary performance and dedication to our customers!

#stackservicespotlight

February 10th, 2020 - Stack Hosts Open House for New Mega Hip Facility in Albany, Oregon

The countless hours of hard work from the Stack team, the City of Albany, Quintus Technologies, Omega Morgan, Messer Gases, Gerding Contractors, NW Bank, and many others came to fruition last week with the Grand Opening celebration for Stack HIP. Over 50 attendees were able to get a first glimpse of the new facility and were able to see our fully operational QIH 286 “Mega-HIP”.

This was a very special day for the entire team at Stack Metallurgical. In addition to our partners and community guests, leadership from all of the Stack sites was present in Albany for the celebration

#hotisostaticpressing #metalpostprocessing #postprocessing

January 23th, 2020 - Stack Spokane Adds New Vacuum Heat Treating Capacity

Stack Spokane has recently expanded its heat treating capabilities with the addition of a new Ipsen TITAN® vacuum furnace. This state of the art H6 2-bar vacuum furnace includes a 36” wide x 36” high x 48” deep graphite hot zone which can process load size of up to 3,000 lbs. The furnace will mainly be utilized to process critical aerospace components. Download the press release to find out more information.

#heattreating #vacuumheattreating #postprocessing #thermalpostprocessing

December 5th, 2019 - Stack Metallurgical Group Augments Hot Isostatic Pressing Capacity with Second System from Quintus Technologies

Västerås, Sweden, December 5, 2019 – Spurred by a successful entry into Hot Isostatic Pressing at the beginning of this year, Stack Metallurgical Group is redoubling its commitment to the technology with the addition of a second Hot Isostatic Press (HIP) from Quintus Technologies. Click the button to download the press release!

#hotisostaticpressing #postprocessing #thermalpostprocessing

Västerås, Sweden, December 5, 2019 – Spurred by a successful entry into Hot Isostatic Pressing at the beginning of this year, Stack Metallurgical Group is redoubling its commitment to the technology with the addition of a second Hot Isostatic Press (HIP) from Quintus Technologies. Click the button to download the press release!

#hotisostaticpressing #postprocessing #thermalpostprocessing

October 17th, 2019 - The Best Time to Build a Roof Is When the Sun Is Shining

This saying definitely rang true this past weekend, as the sun shone down on our new facility in Albany, OR. The team is working seven days a week to prepare for the arrival of HIP Unit #1, a Quintus QIH 286 “mega HIP”. The project remains on-schedule, and we are excited to launch HIP services in Q1 2020. Keep checking back for more updates!

#hotisostaticpressing #heattreating #postprocessing #thermalpostprocessing

August 26th, 2019 - If You Build It, They will Come

The age-old adage rings true, even in the world of metal post processing. Construction is moving forward at a brisk pace at our new, highly anticipated Albany, Oregon site! The pit construction is officially complete, the main slab poured, and the walls are now being constructed. We will proudly offer both Hot Isostatic Pressing (HIP) and vacuum heat-treating services at this facility. Click on the pictures below to see updates on the site which will house one of the largest HIPs in North America. Keep checking back for more updates, and make sure to follow us on social media for live updates!

#hotisostaticpressing #heattreating #postprocessing #thermalpostprocessing

July 7th, 2019 - You Can't Build a Great Building on a Weak Foundation

After months of meetings with contractors, the city of Albany, and the state of Oregon, Stack Metallurgical Group (SMG) has officially began the process of constructing the Albany facility plant! Dozens of people (both contractors and SMG staff) are on site daily, seven days a week working with the robust project. That is over 25,000 square feet of space devoted for metal post processing, the facility will be the one of the most innovative thermal post processing facilities in the country.

Make sure to keep checking back for updates!

#hotisostaticpressing #heattreating #postprocessing #thermalpostprocessing

Harold Stack: July 5, 1915 - June 14, 2019

Harold E. Stack, age 103, passed away peacefully at his home in Madison Park on June 14, 2019. Seattle born and raised, Harold graduated Roosevelt HS in 1933 and from UW in 1937 lettering in Skiing and a member of Phi Sigma Kappa. Active sailor, skier, fisherman, served in US Navy for over 5 years during WWII, departed at rank of Cmdr., then rejoined family steel distribution business started by his father. Innovative, industrious and active locally and with the Steel Service Center Institute, Harold grew Stack Steel and Supply Co. with the help of many loyal employees to a regional business with branches in Seattle, Spokane, Anchorage and Portland.

Selling the business in 1977 to fully retire, he and Trudy enjoyed snow birding from their Windermere home of 55 years to Rancho Mirage for 30 seasons making many new friends, dining, dancing and golfing at Thunderbird CC. Married 70 years before losing Trudy in 2013, Harold carried on solo but with truly exceptional help from a staff of loving caregivers. Children Sally, Nancy, Robb, Katie and spouses, plus 6 grandchildren and 8 great grandchildren can’t thank them enough for the compassion they showed keeping Dad healthy and safe in his last few years. Harold was a man of many interests and talents collecting NW art, amassing a prominent collection of ancient carved jade, piloting his own airplane with IFR ticket, growing apples in Tieton and developing real estate. Fishing was his true passion that was shared by best friend and attorney Bob Purdue…….always in pursuit of the “Big One”.

Harold and Trudy affected the lives of many with their philanthropy and especially by granting tuition scholarships at UW to deserving graduates from their respective high schools…..Roosevelt and Garfield. He was a UW Tyee member for nearly 70 years, a member of Seattle Yacht Club since 1939, Broadmoor Golf Club starting 1961, the WAC since 1952, and he was a founding member of Columbia Tower Club plus a founding shareholder in Crystal Mountain. Harold was truly one of “The Greatest Generation” who had many interests and accomplishments. No service is planned so just raise your glass and toast to a good man.

January 7, 2019: Stack Metallurgical Group to Enter Hot Isostatic Press (HIP) Market

Stack Metallurgical Group (SMG) will be entering the Hot Isostatic Press (HIP) market in 2019 with the addition of a QIH 286 “Mega-HIP” manufactured by Quintus Technologies. Based in Västerås, Sweden, Quintus is widely-regarded as the global leader in high-pressure equipment and solutions. The addition of HIP will further expand the service offerings of SMG to key customers in the aerospace, medical implant, additive manufacturing, and power generation industries.

The equipment being constructed for Stack will offer some of the largest capacity available not only in the Northwest United States, but around the globe. It will be equipped with Quintus’ proprietary uniform rapid cooling and features a large-capacity work zone of 63 inches (1,600 mm) in diameter and 102 inches (2,591 mm) in height, allowing densification of large batches at 29,000 psi (2,000 bar) and a maximum operating temperature of 2280°F (1,250°C).

“We are truly delighted to bring large-scale HIP capacity to the Northwest U.S. market,” according to Doug Puerta, CEO. “HIP is a complimentary service to our existing portfolio of offerings. Stack has always worked closely with its clients to make smart investments to support their metal processing needs. By expanding into HIP, we’ll be in a position to offer a really outstanding value proposition of capability, capacity, quality, and service.” Dave Ederer, Chairman of SMG adds “This is an important extension of Stack’s business philosophy of providing new technology to its established customer base.”

“Stack HIP” will be based in a brand-new 25,000 sq. ft. facility in Albany, OR. This will be the fourth location for SMG, and will complement existing heat treat and metal processing facilities in Portland, OR, Spokane, WA, and Salt Lake City, UT. Construction of the new HIP facility is underway and will be completed in mid-2019, with equipment installation to immediately follow.